Speed

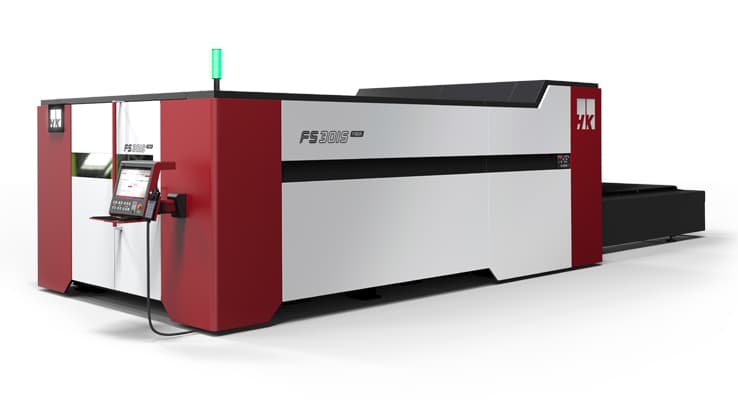

Affordable metal sheet & pipe fiber laser cutter is a type of automatic CNC laser metal cutting system not only for metal sheets and metal plates with different thickness, but also for metal pipes and metal tubes with different shapes.

Raycus 50W Fiber Laser can be used to etch and mark aluminum at 90 degrees angles. It uses 100% of the laser's power.